Technology for every need

FARM BRASS has a technical office that interface with clients, both artisans and big industries; either small plants, complete molding lines or Heat Treatment lines. In this way we can give a constant support, offering a detailed service tailore studied according to the needs.

Each installation is treated in every detail for every kind of need with the most modern machinery .

The heating plant realization it’s our bread and butter. We offer tailored and innovative solutions to answer to the most veried needs of our customers.

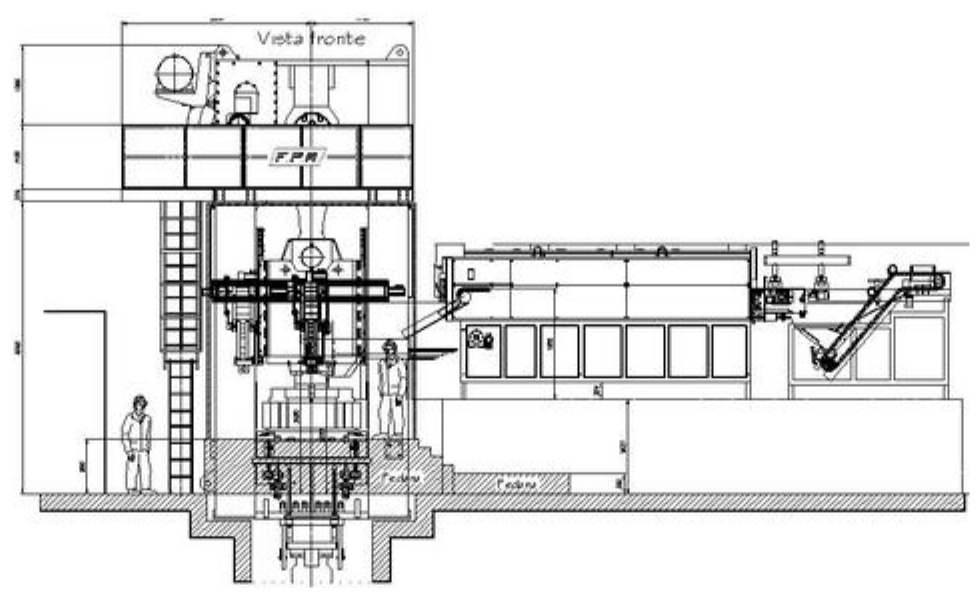

We are able not only to propose standard installation from our wide range, but also to build installations dedicated to a special processing, or to a special molding line matching machinery from our production or from our trusted partners, as F.P.M. Group and Zobbio transfer.

is always searching constructive groundbreaking solutions to be applied to all products.

Nothing is left to chance and we totally follow the project: from the draft to the transport to the customer’s headquarter, caring mostly the materials analyzes, the costs and the tests.

Our technical office is able to design and develop, in synergy with the client, the best product needed. Experience, professionality and a great collaboration service guarantee the great quality of our products certified CE and according to the law.

The plants are designed to meet heat treatment regulations for accreditation in both corporate quality manual processes, such as the automotive industry standard IATF 16949 and CQI-9 heat treatment process evaluation, and in the aerospace industry such as Nadcap and associated specifications, including AMS2750.

The technical office use powerful computers with specially softwares dedicated to the metal heating sizing for the design.

We are able to interface to the main systems of CAD drawing used by design studies or by our customers’ technical offices in order to make them follow and discuss all the progress of the project simply sending the updated tables.

Thanks to a product in-depth study we can offer the best solutions, leaving nothing to chance we carry on the project and the research both for the complete customer’ satisfaction.

PROJECT + RESEARCH = SOLUTION

Here our winning equation!

At customers' disposal

We dedicate a particular attention to the product, we always research a continuous improvement with extremely technological and innovative machinery.

A particular sensitivity to listen, understand and take to the project the clients’ needs is what identify us. We make available to our customers an important asset of experience and problems solved on the most varied heating applications within industrial processes. We are completely available for a pre (draft, advices, inspections…) and post sale support.

Since ten years a new young management is guiding the company to new and ambitous targets on the nationa and international market.

Company’s pride and joy are our dynamicity and our resourcefulness, we put the client to the centre of the project, supporting him with a team of experts in every working phase.

We are able to propose technical and functional solutions to be applied to existing plants (new or obsolete) even of the competition.

We design parts installable on our previously constructed installations, trying to not modifying a lot the machines in order to limit the costs.

Safety regulations are constantly updated and often the obsolete machinery have to be reviewed in some parts as they have been built before of the actual laws.

For example we can intervene adding soundproofing cabins or components for the heating plant or adding, if it is possible, non provided accessories at the purchase ( drain device, groups for the discs or plate molding … ); we can also transform plants with a limited production into new boosted ones in order to satisfy customers’ new needs.

We operate following the rules imposed by law, in order to offer a guaranteed product putting our experience and our professionality to customer’ service.

We can also run projects and chages on non FARM BRASS‘ machinery and plants.

Our partners

Since more than 30 years is specialized in buying and selling of transfer machineries activities, these machineries are used as horizontal and vertical units, with different number of unit, suitable to the lavoration of: fittings, valves, taps, automotive, general mechanical machining. The company realizes also revisions on Transfer machines.

FPM is a leader in the production and revision of presses and metal stamping installations. Since 1986 it rose, innovating and using the most innovative technologies, in order to offer high quality productive solutions to their customers all around the world.

ZB, è un’ utensileria meccanica, specializzata nella costruzione di attrezzature per macchine Transfer e nella progettazione e realizzazione di sistemi presa pezzo. La specializzazione in tali attrezzature ha permesso a ZB di annoverare fra la sua clientela aziende leader nel settore della rubinetteria cromata, valvolame e raccorderie.