S.Q. series Used & Overhauled Furnaces

Availability of a wide number of optionals for specific production needs.

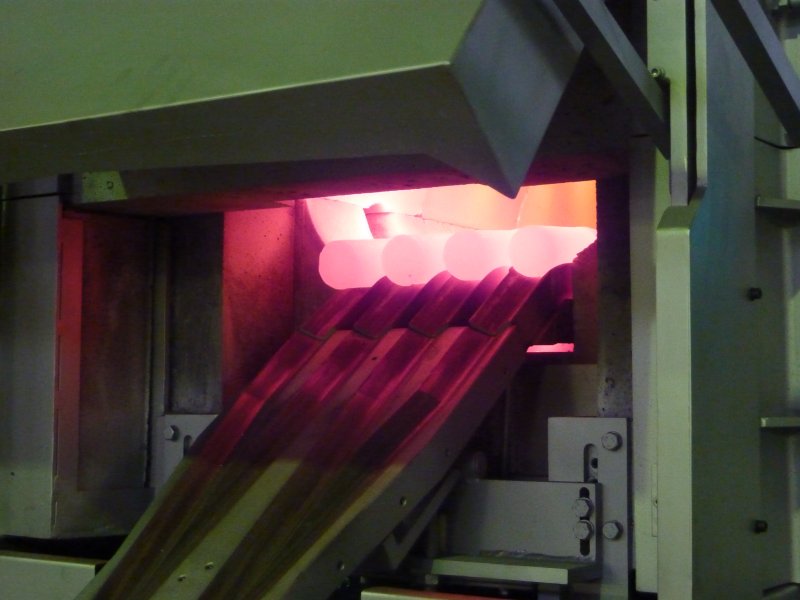

Temperature regulation by proportional modulating action, allowing temperature uniformity to be +/- 0.5% of preset value. Check up by thermocouple for entrance and central zones; by optical pyrometer for the exit zone. Direct heating by burners on the heating chamber vault and flame on tracks.

Tracks stand on steel rods, not directly on refractory, these determines a more uniform heat transfer on tracks: less oxidant of the parts, preservation of graphite features (if used) less bending and longer lasting of tracks, easiness in cleaning the heating chamber hearth.

Four chamber length are available: SQ180, SQ240, SQ300, SQ360 (all 2 zones), where model number indicates length in mm. Every chamber can be provided by racks, having wheelbase 50mm.

Feeder/In-column device AC (pieces L.100), AS (pieces L.150), AL (pieces L.300).

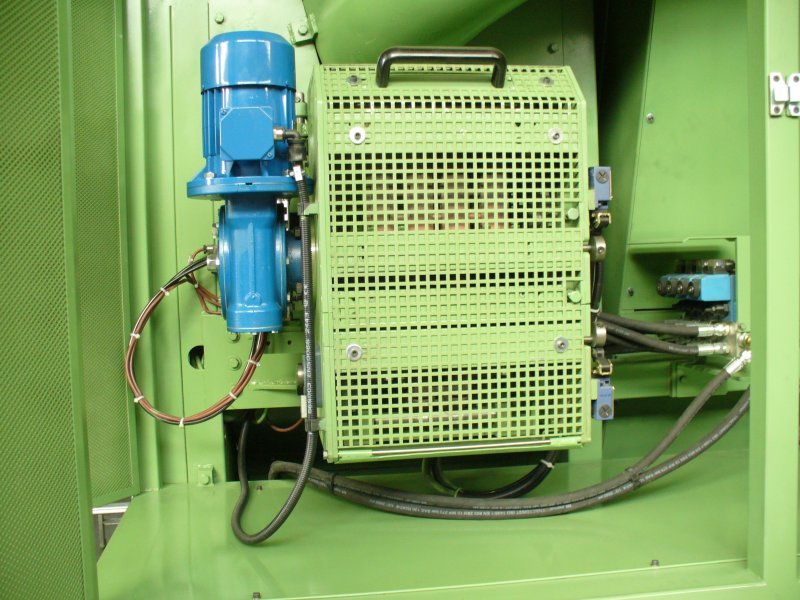

Electrical switchboard and operator panel, both beside the machine, included. Feed logics by PLC.

Caratteristiche tecniche