I.G.O. series Gas Thrust Furnaces

Availability of a huge number of optionals for specific production requirements.

Designed to allow maximum productivity with minimum overall dimension, these solve more and more present needs of limitation in available room with increased quantity produced.

Temperature regulation by proportional modulating action, allow ing temperature uniformity to be +/+ 0.5% of preset value. Check up by thermocouple on one or two zone, according to heating chamber length.

Direct heating by burners on the heating chamber vault and flame on tracks.

In 2G version, tracks wheelbase is 80 mm (parts diam. 15-60mm) or 120 mm (parts dial, 15-80 mm). in 3G version wheelbase is 75 mm (parts diam. 15-60 mm§); in 4G it is 50 mm (parts dial. 15-45 mm).

Four chamber lengths are available: IGO2000, IGO2500 (1 zone) and IGO3000, IGO300 (2 zones), where model number states length in mm. Every chamber can be provider by 2, 3 or 4 tracks according to required production and size of parts to be heated.

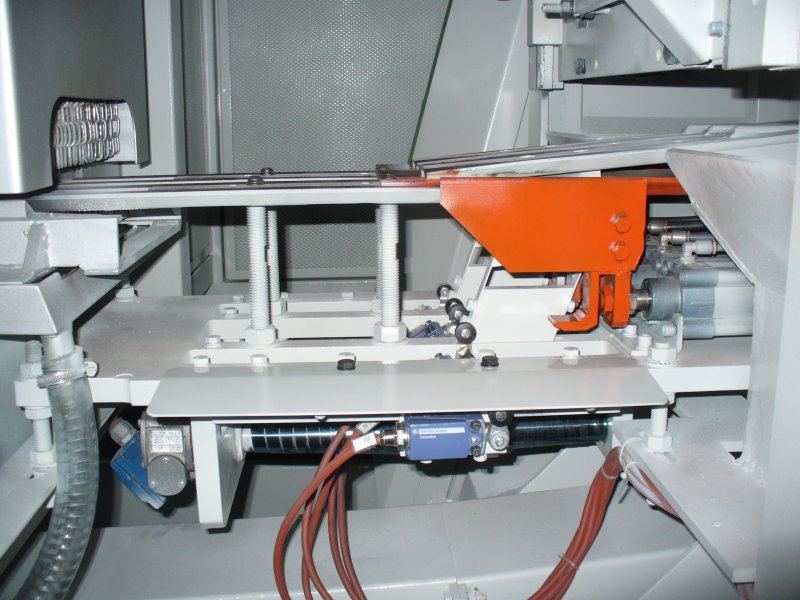

Feeder/In-column device A1300(pieces length 200 mm) A1600 (pieces length 300 mm).

Electrical switchboard and operator panel beside the machine included.

Feed logics by electromechanical relays or PLC.

Temperature regulation by microchip thermoregulator.

Caratteristiche tecniche