This research allows you to find an standard oven model based on the parameters you selected (materials, works, accessories, ecc...)

This search allows you to find the oven model by searching for any term within the titles, descriptions, and features

N.O. series Gas Chain Furnaces

N.E. series Gas Chain Furnaces

I.G.T. series for Aluminium Forging

I.G.M series Gas Thrust Furnaces

I.G.Q. series Gas Thrust Furnaces

I.G.O. series Gas Thrust Furnaces

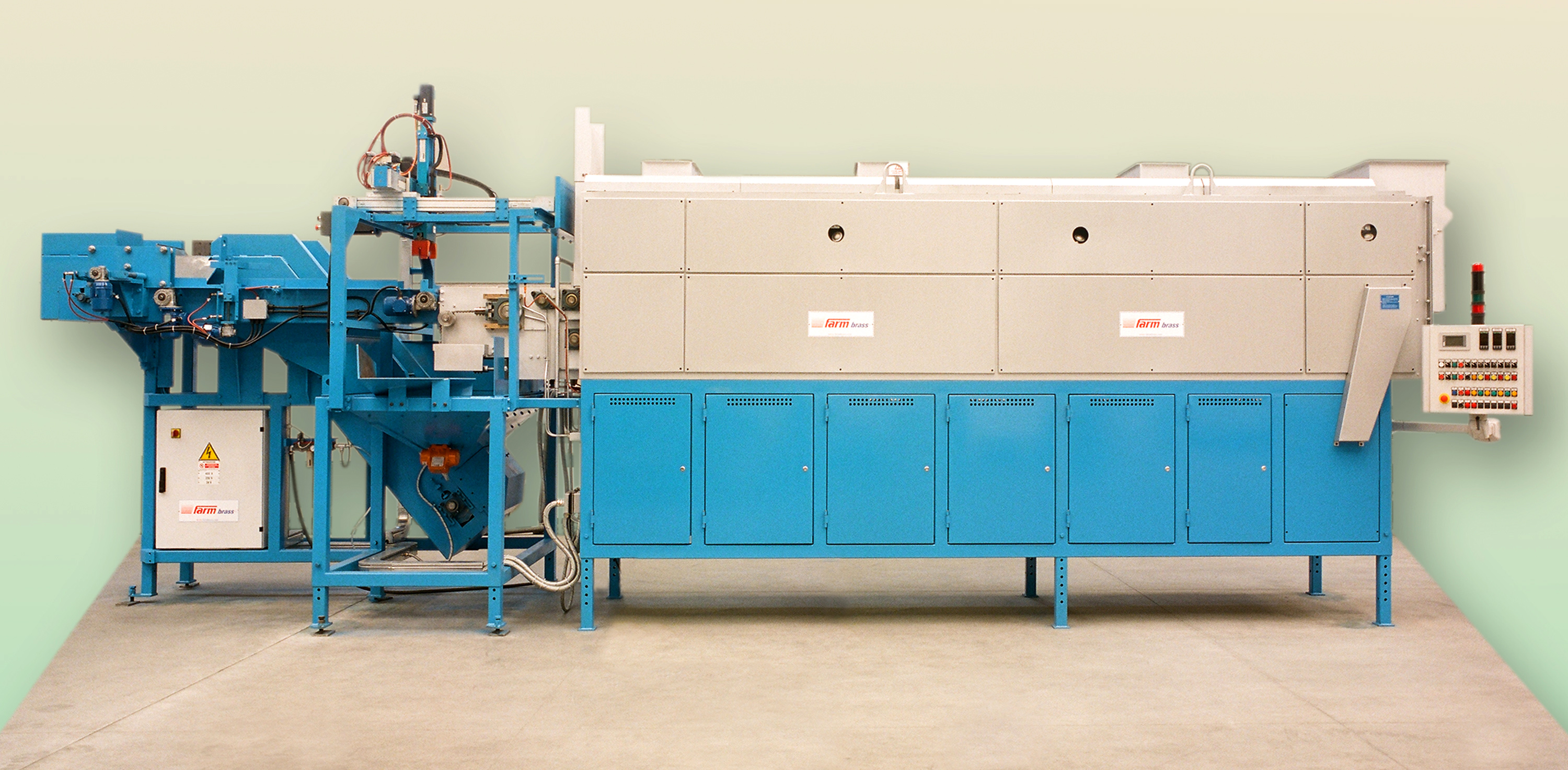

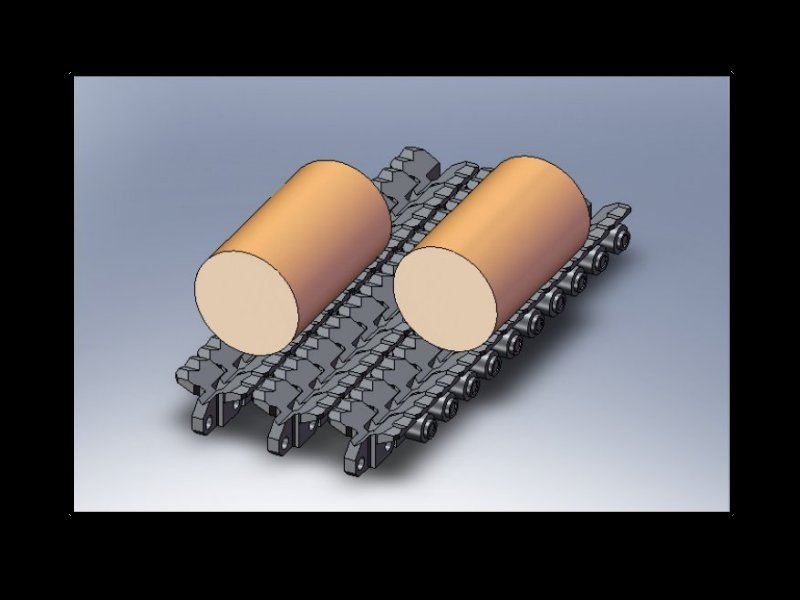

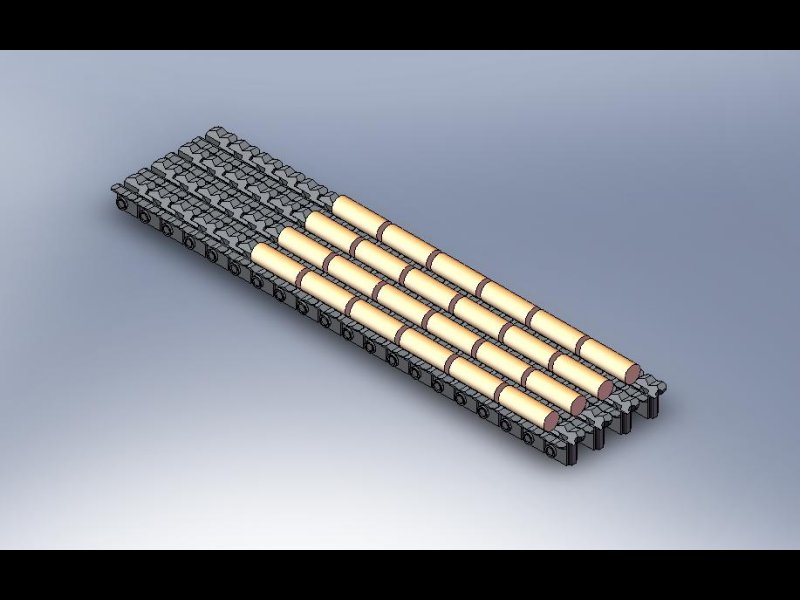

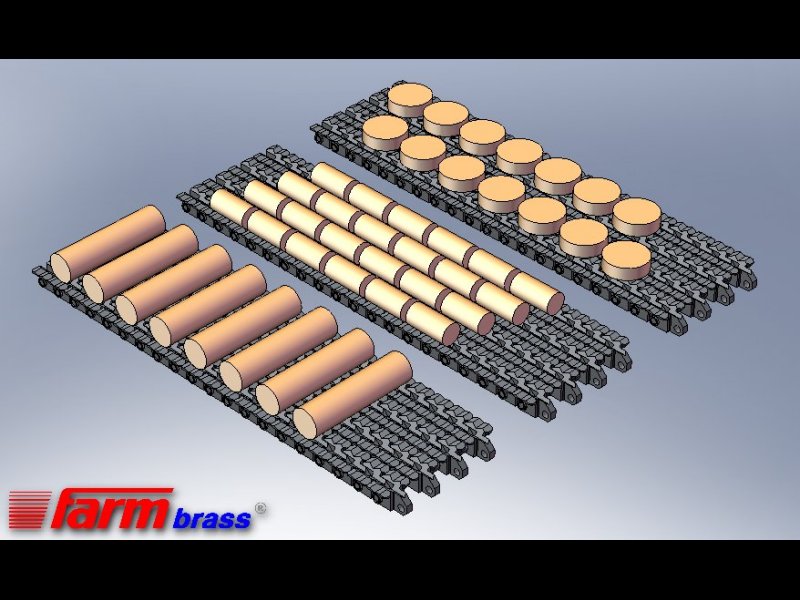

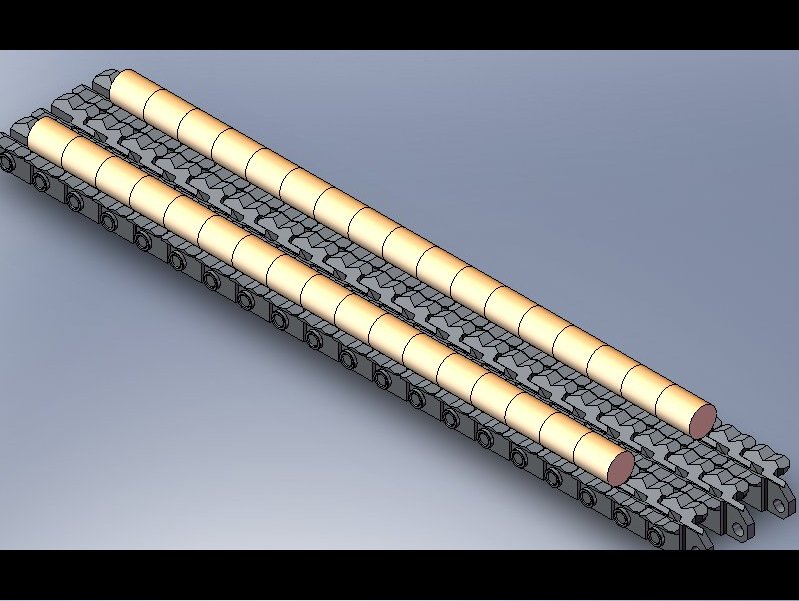

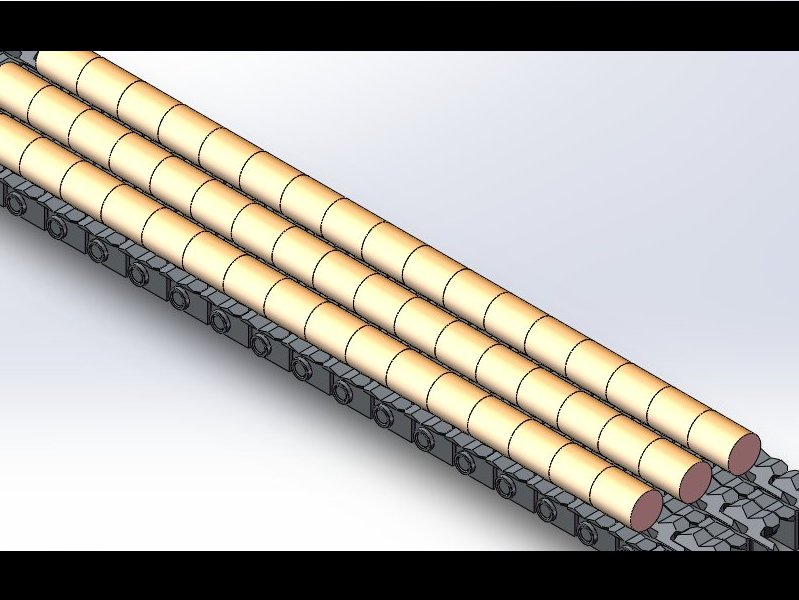

N.O. series Gas Chain Furnaces

The new range of furnaces, N.O. series offers come technical improvements to perfect functioning.

It is built up to respond to growing demand for pre-formed parts, squares and discs heaving having huge size.

Huge number of optionals available, according to specific production needs.

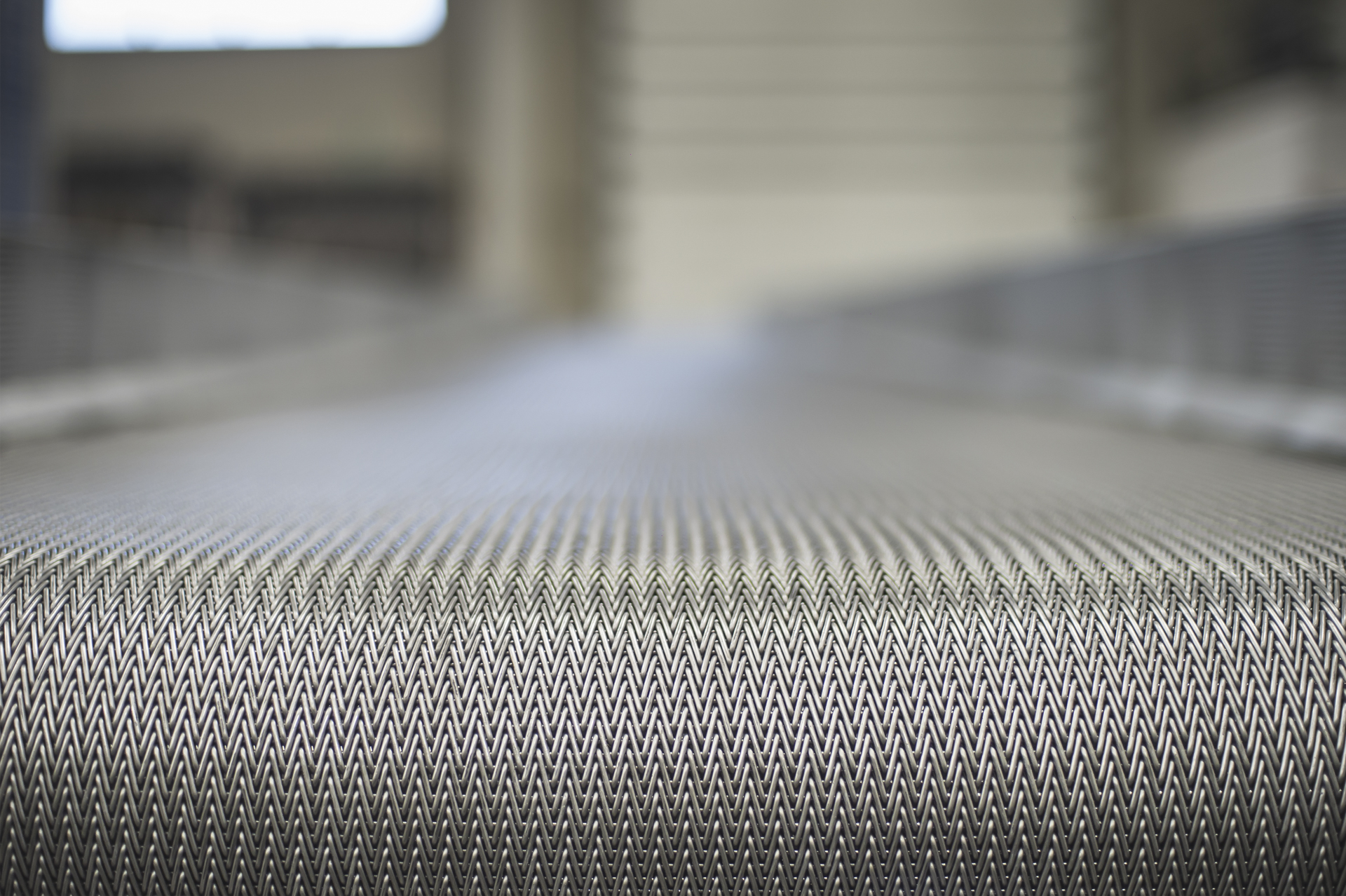

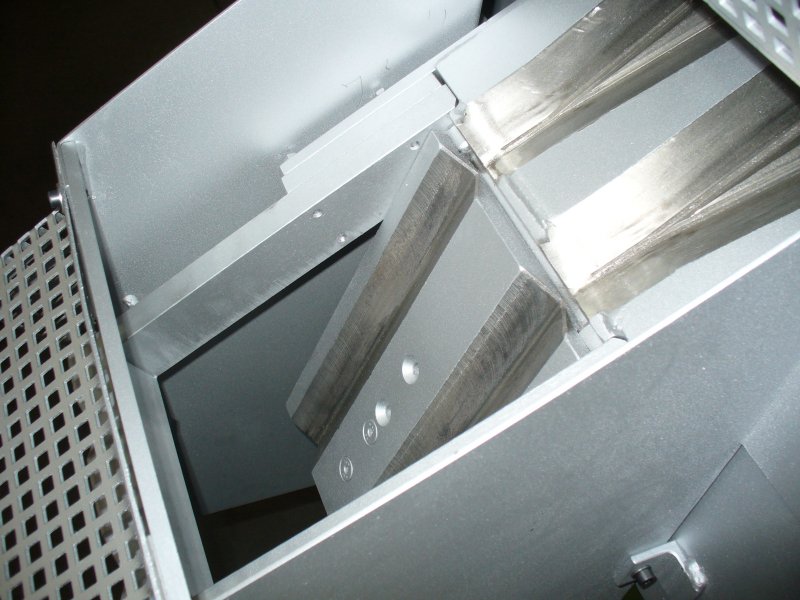

The chain, patented, is integrally made by AISI310 stainless steel and it is held into an insulated chamber, granting temperature stability, allowing strong energy saving and long lasting working conditions.

The chain can be completely slipped off the machine body, allowing easy maintenance and the possibility to replace single links.

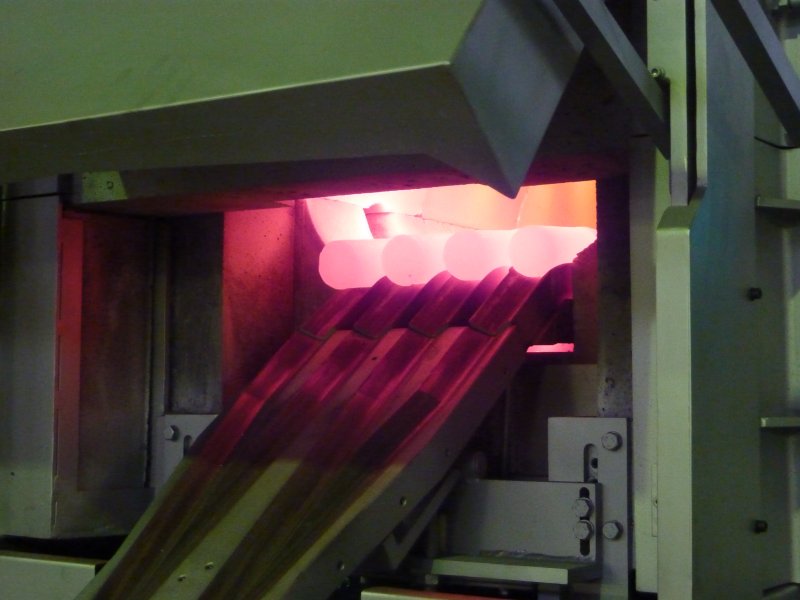

Temperature regulation by proportional modulating action, allowing temperature uniformity to be +/- 0.5% of preset value. Check up by thermocouple for all zones and by added optical pyrometer only for the exit zone. Direct heating by burners on the heating chamber vault and flame on belt.

Uniform heat transfer on belt less oxidation of the parts, preservation of graphite features (if used).

Chamber lengths are available starting fro NO3000 up to NO5400 (all 3 zones), where the model number states the length in mm. The chamber is provided by 3, 4 or 5 link lines, side by side, having wheelbase 60, 65, 70, 75, 80, 85, 90 and 95 mm, according to production needs.

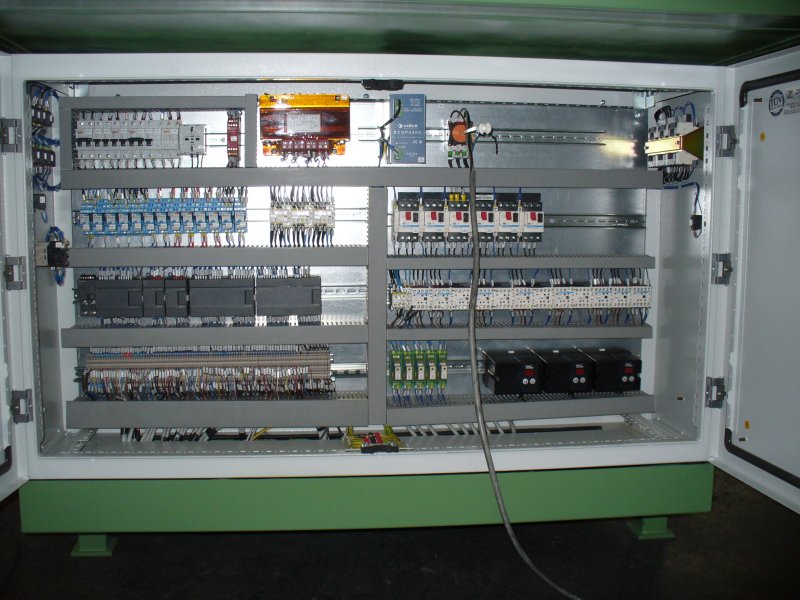

Electrical switchboard and operator panel, both aside the machine, included. Feed logics by PLC.

Temperature regulation by microchip thermoregulator.

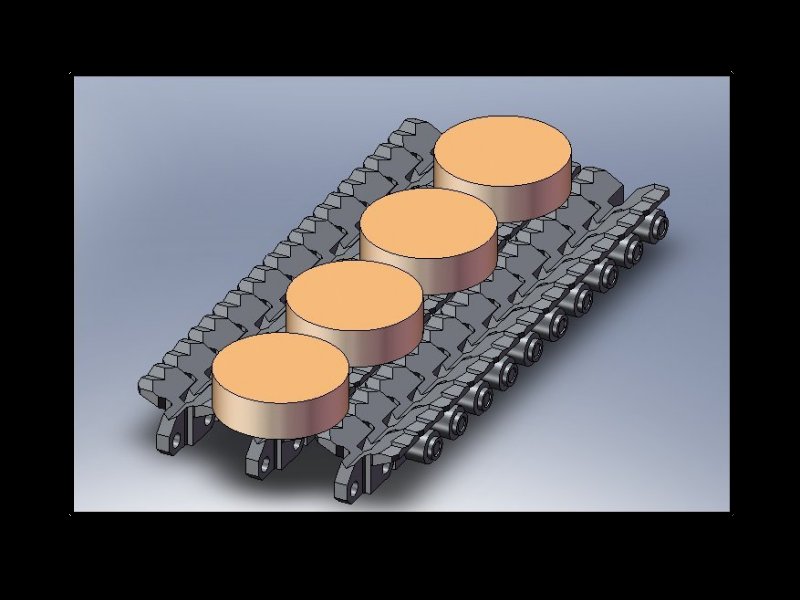

N.E. series Gas Chain Furnaces

Huge number of optionals available, according to specific production needs.

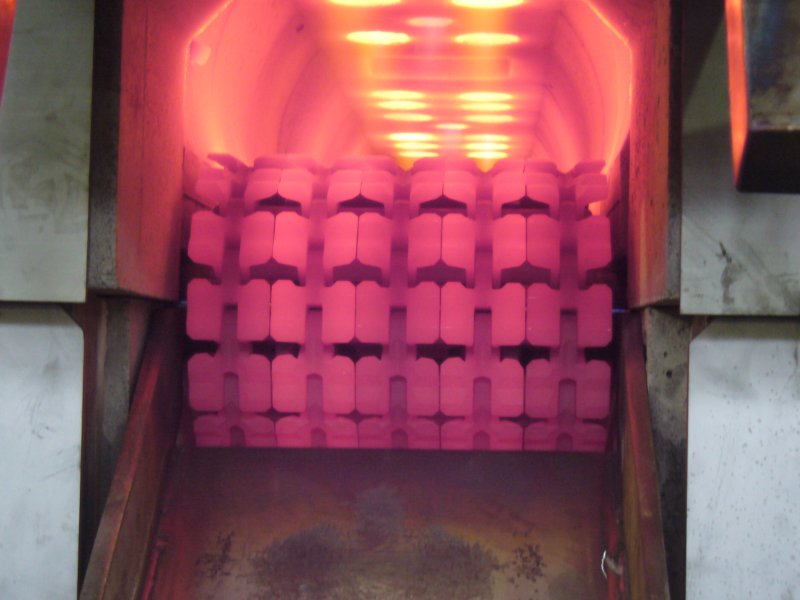

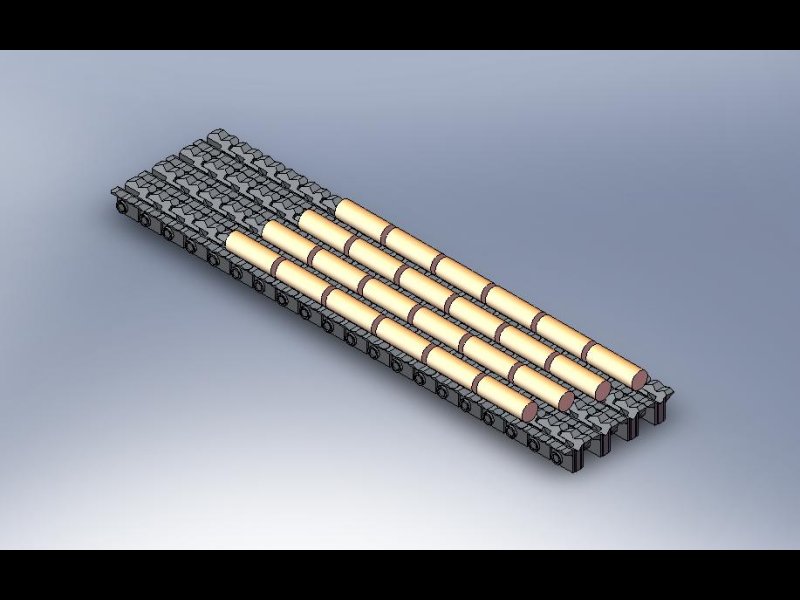

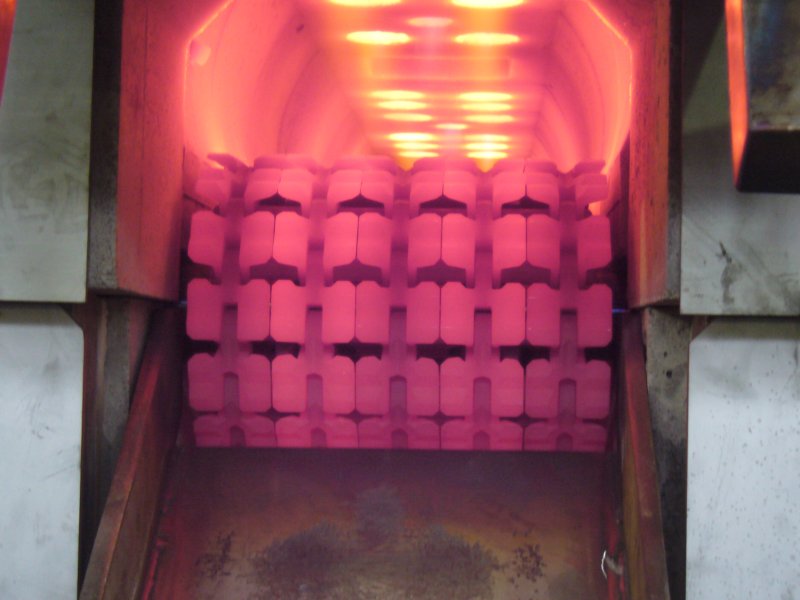

I.G.T. series for Aluminium Forging

The handling of the pieces inside the heating chamber takes place by means of a belt of

stainless steel mounted on a removable structure to facilitate maintenance. The group of

handling protrudes from the chamber to allow manual loading of the pieces.

The belt (patent pending) is entirely built in AISI310 steel guarantees stability of

temperature with strong energy saving and long service life. The carpet can be

completely extracted from the machine body allowing easy maintenance and cleaning.

Modulating proportional action temperature regulation. Multiple detection on each

single zone via thermocouple. Indirect heating with high thermal power burners.

Different chamber lengths are available and can be equipped with belts from 400 to 1000 mm

according to production needs.

It includes an electrical panel and an operator panel on the machine.

Progress logic a

PLC.

Temperature regulation by means of a microprocessor thermoregulator.

Independent burner boxes placed near each single burner with ignition and flame detection equipment.

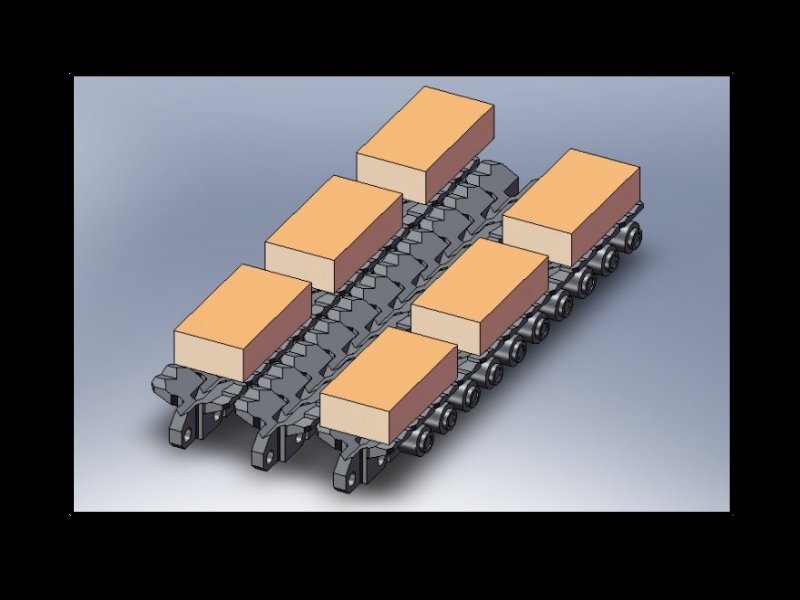

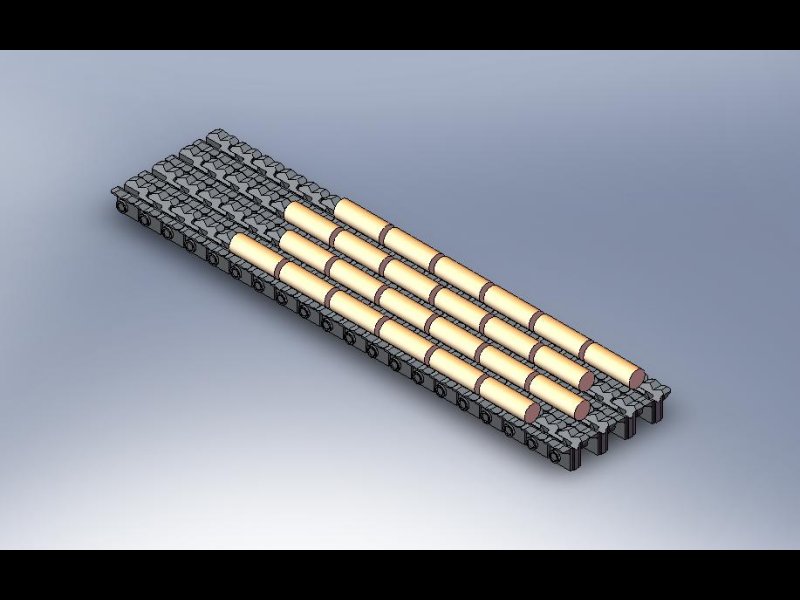

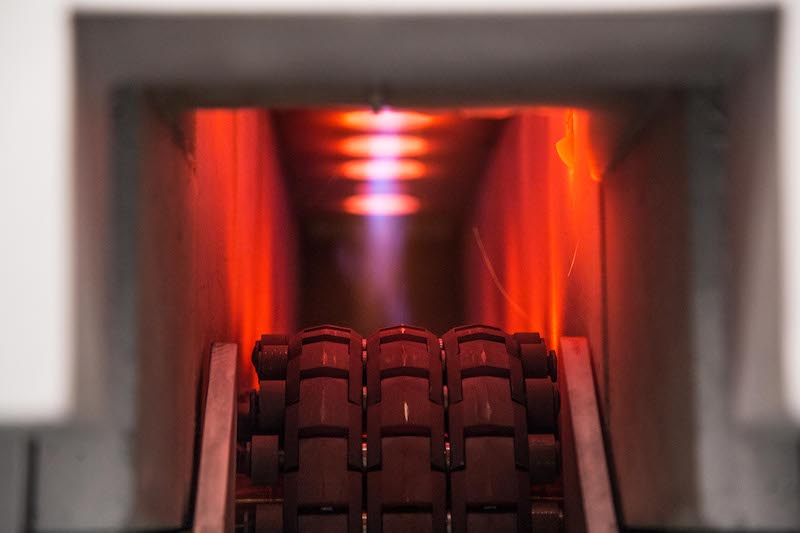

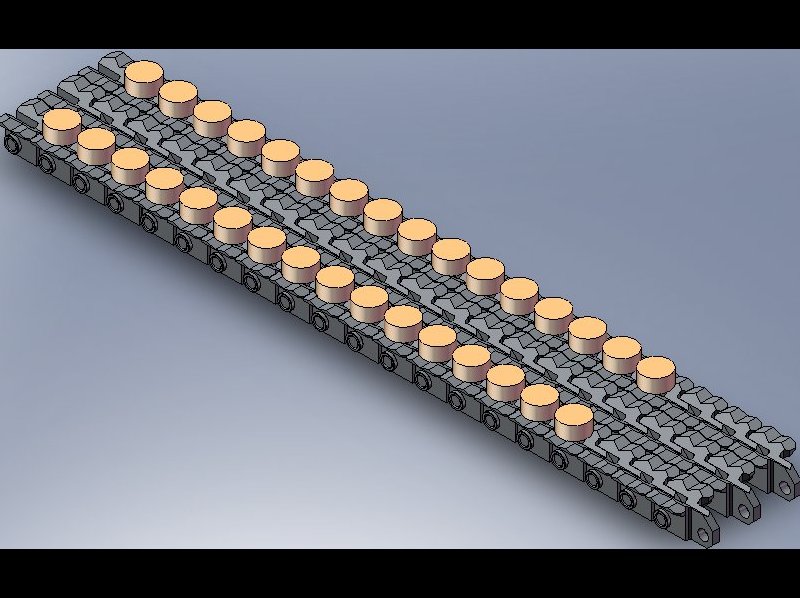

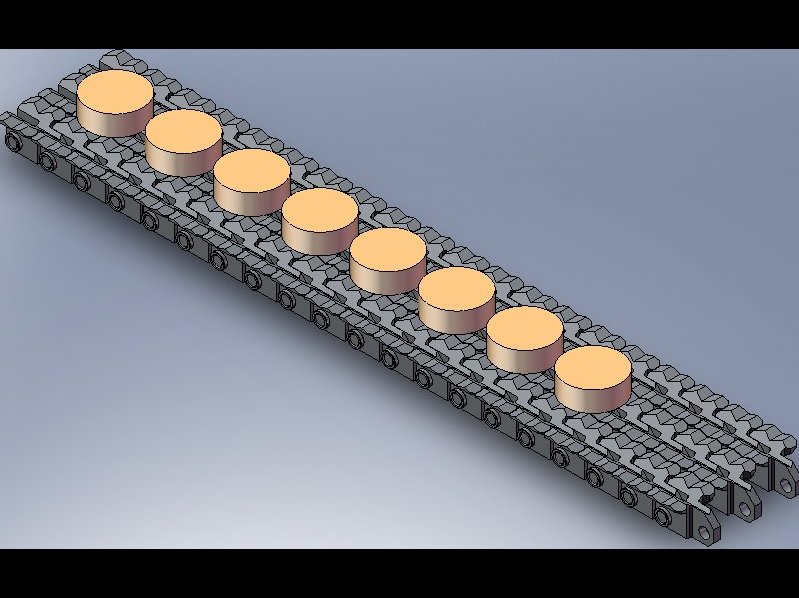

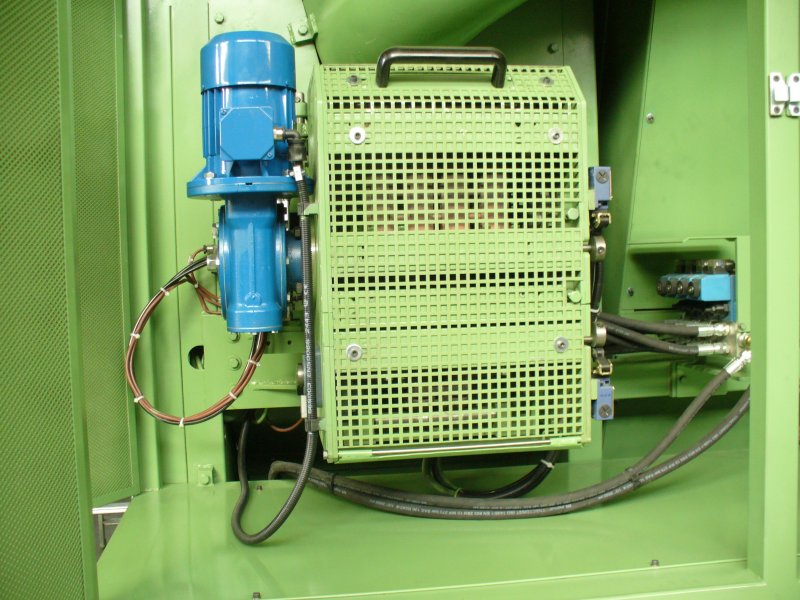

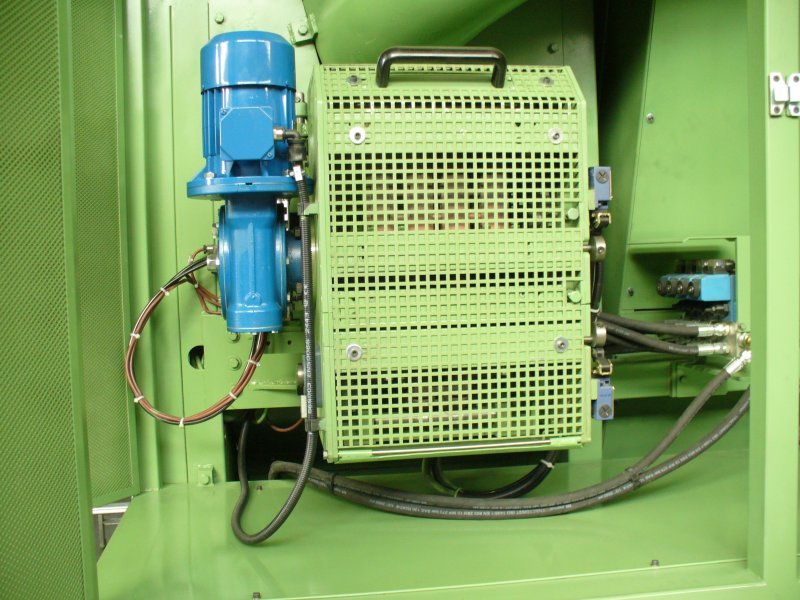

I.G.M series Gas Thrust Furnaces

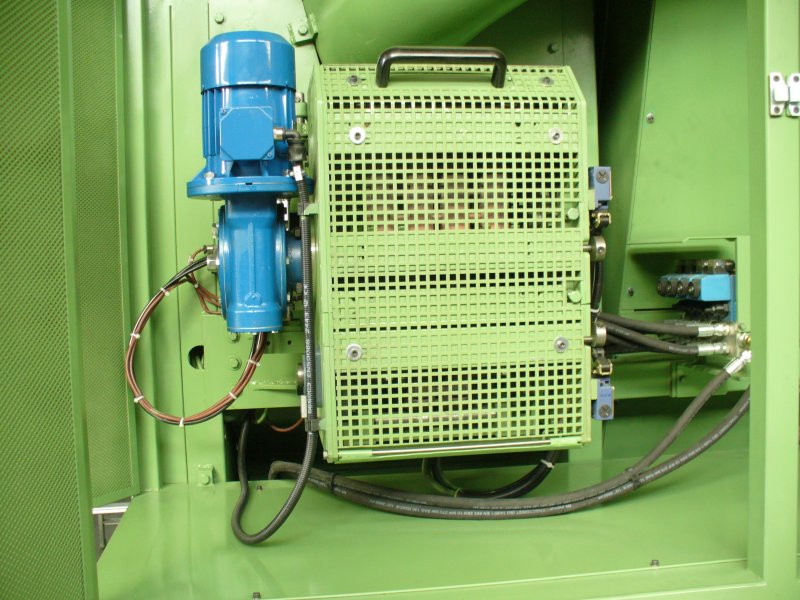

Availability of wide number of optionals, according to specific product requirements.

These distinguish for their extreme use versatility and conduction simplicity. Designed to allow maximum productivity with minimum overall dimension, these solve more and present needs of limitation in available room with increased quantity produced. These are suitable for precision heating of huge quantity of small, medium and large parts (maximum weight: 8 kilos/part).

Temperature regulation by proportional modulating action, allow ing temperature uniformity to be +/- 0.5% of preset value. Check up by thermocouple for entrance and central zones; by optical pyrometer for the exit zone. Direct heating by burners on the heating chamber vault and flame on tracks.

Tracks stand on steel rods, non directly on refractory; these determines a more uniform heat transfer on tracks: less oxidation of the parts, preservation of graphite features (if used), less bending and longer lasting f tracks, easiness in cleaning the heating chamber hearth.

Six combustion chamber lengths are available: IGM2600 (2 zones) and from IGM3200 to IGM5100 (3 zones). where the model number states the length in mm. The chamber is provided with 3 Tracks having 120 mm wheelbase (pieces diam. 25-100 mm) or 4 tracks having wheelbase 80 mm (pieces diam. 25-60).

Feeder/In-column device A1600 (pieces L.350).

Electrical switchboard and operator panel, both at the machine edge, included. Feed logics by PLC.

Temperature regulation by microchip thermoregurator.

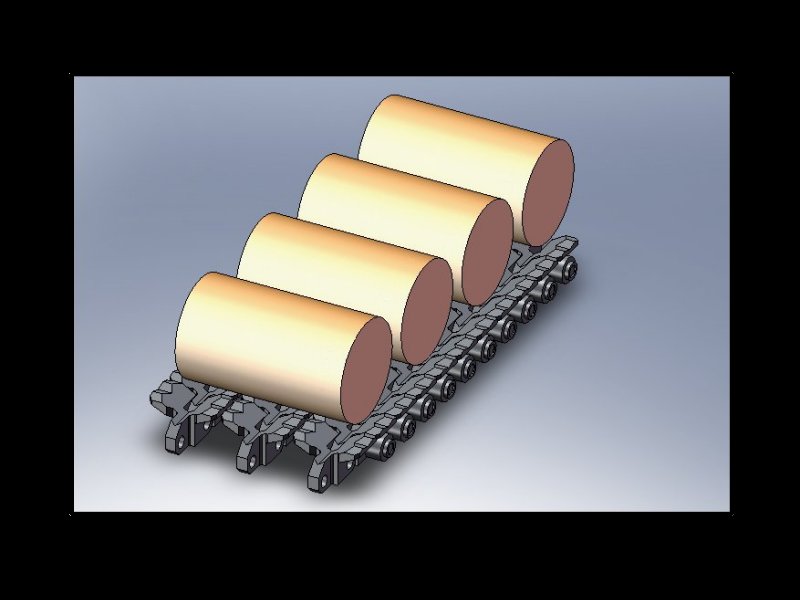

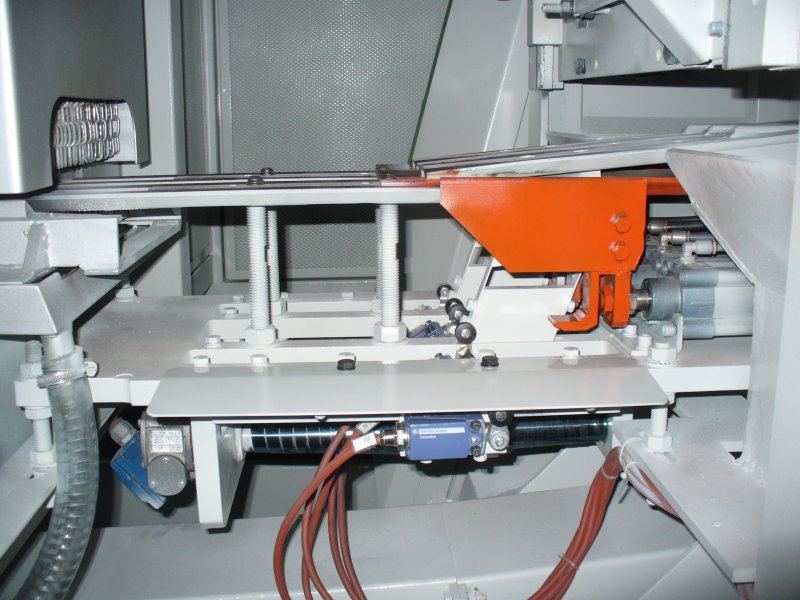

I.G.O. series Gas Thrust Furnaces

Availability of a huge number of optionals for specific production requirements.

Designed to allow maximum productivity with minimum overall dimension, these solve more and more present needs of limitation in available room with increased quantity produced.

Temperature regulation by proportional modulating action, allow ing temperature uniformity to be +/+ 0.5% of preset value. Check up by thermocouple on one or two zone, according to heating chamber length.

Direct heating by burners on the heating chamber vault and flame on tracks.

In 2G version, tracks wheelbase is 80 mm (parts diam. 15-60mm) or 120 mm (parts dial, 15-80 mm). in 3G version wheelbase is 75 mm (parts diam. 15-60 mm§); in 4G it is 50 mm (parts dial. 15-45 mm).

Four chamber lengths are available: IGO2000, IGO2500 (1 zone) and IGO3000, IGO300 (2 zones), where model number states length in mm. Every chamber can be provider by 2, 3 or 4 tracks according to required production and size of parts to be heated.

Feeder/In-column device A1300(pieces length 200 mm) A1600 (pieces length 300 mm).

Electrical switchboard and operator panel beside the machine included.

Feed logics by electromechanical relays or PLC.

Temperature regulation by microchip thermoregulator.

Contestual research:

Search by term

No product matches your request.

N.O. series furnaces.

Built up to respond to growing needs in heating pre-formed parts, squares, discs, having al so huge sizes “V” profiles machined on the belt allow, moreover, easy line-up the parts on more files, letting the system be of universal use.

N.E. series furnaces.

The new furnaces product range, N.E. SERIES, performs the same heating quality as N.O. SERIES, having the advantages of lining - up device used for Thrust Series.

It is built up to respond to growing demand for pre-formed parts, squares and discs heaving having huge size.

The Gas Belt Furnaces IGT SERIES, dedicated to heating for forging and stamping aluminum, are

stand out for their high quality and versatility of performance. The uniformity of the temperature,

essential condition in the molding of light alloys, is obtained with the indirect transfer of

heat through the conveyance of hot air on the piece conveyor belt.

I.G.M. series furnaces complete the series range and distinguish for the very high thermic potential, ensuring very high hours production with the best heating quality. Produced in 3 or 4 tracks version, I.G.M. furnaces are designed to allow high productivity also in presence of extremely limited room available. The evolution trend in hot forging has stimulated perfectioning of quality features of furnaces in terms of temperature uniformity and production velocity. The answer to these requirements is realized by this series of furnaces thanks to the use of sophisticated temperature detection and regulation systems.

I.G.M. furnaces have been designed to feed new generation press machines for automatic stamping of one, two or four figures.

I.G.O. series furnaces

Great use versatility, functionality and reliability are the main featured of wide and differentiated range, designed to stamp a single parto arm two parts simultaneously. These furnaces have been designed to allow high productivity.also with extremely limited room available.